Patterned conveyor belt

If you need customized products, Contact US !

Category

Tag list

- 产品描述

-

Product Introduction

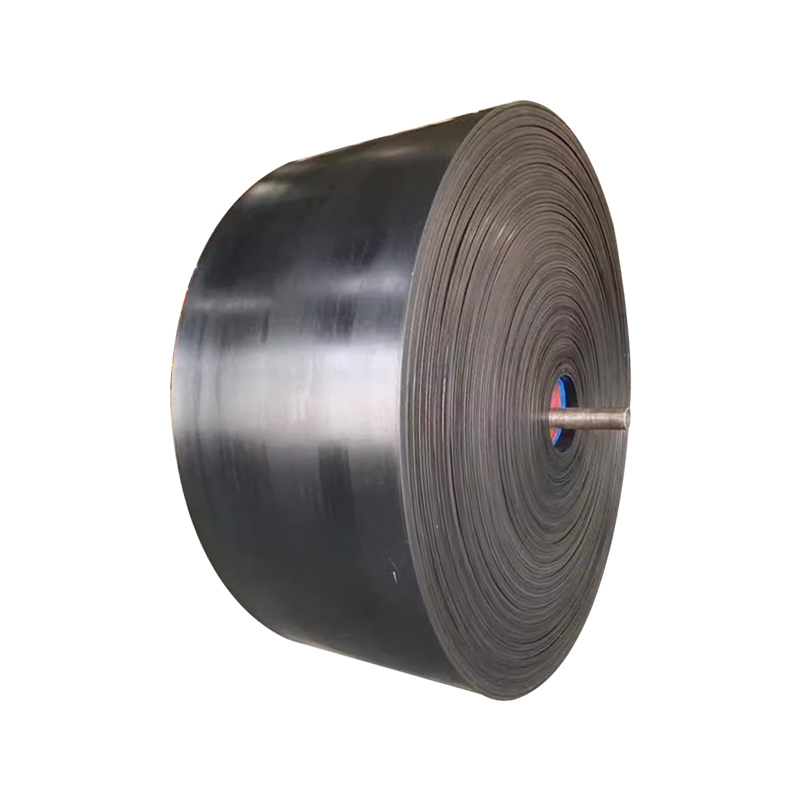

Patterned conveyor belts are a special type of conveyor belt characterized by various patterns on the belt surface. These patterns are designed to enhance friction between the conveyor belt and the material, making them suitable for material conveying at different angles. Below is a detailed introduction to patterned conveyor belts:

Definition and Uses

Patterned conveyor belts consist of a belt body and a patterned section. Their primary function is to enhance grip between the conveyor belt and the material, preventing slippage or dropping during conveying. The shape and height of the pattern vary depending on the material being conveyed and the angle of the conveyor. Common pattern types include herringbone, striped, granular, and fan-shaped, suitable for conveying materials with different angles and types.

Common Types and Their Characteristics

Herringbone Pattern: The belt surface features raised herringbone patterns, suitable for conveying powdery, granular, and small-piece materials at angles ≤40 degrees. It can also be used for conveying bagged materials.

Striped Pattern: The belt surface features horizontal stripes, suitable for horizontal conveying of packaged goods at angles ≤30 degrees. In a troughing condition, it can replace the herringbone pattern.

Granular Pattern: The belt surface features raised or recessed granular patterns, suitable for conveying soft packages or materials requiring grip, such as cardboard boxes, or granular materials at angles ≤45 degrees.

Fan-shaped Pattern: The belt surface features semi-circular fan-shaped patterns, suitable for conveying powders, granules, and block-shaped materials at steep angles ≤60 degrees.

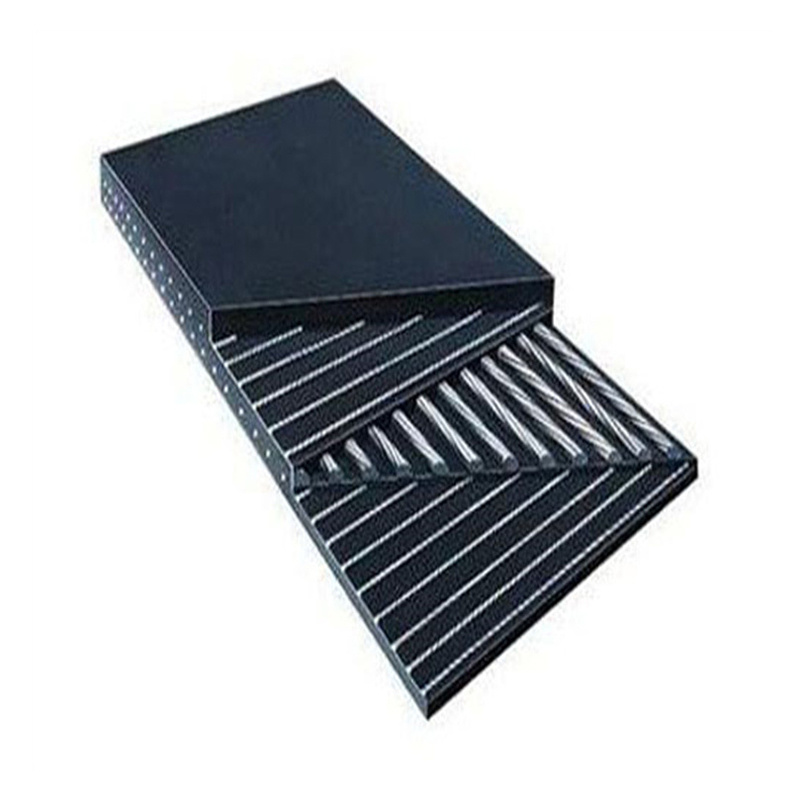

Materials and Manufacturing Process

Materials for patterned conveyor belts include ordinary cotton canvas, polyester-cotton blended canvas, nylon, and polyester. These materials offer good strength and wear resistance, adapting to various working environments.

In the manufacturing process, the patterned section is created by adding a patterned mold to the belt body or by directly processing the belt surface, ensuring a firm bond between the pattern and the belt body.

Maintenance and Care Methods

To extend the service life of patterned conveyor belts, regular maintenance and care are necessary. Specific measures include:

Regularly clean the conveyor belt surface to prevent debris accumulation from affecting the pattern's effectiveness.

Inspect and repair worn pattern sections to prevent overall performance degradation due to localized wear.

Keep the conveyor belt clean and dry, avoiding prolonged immersion in water or contact with corrosive substances.

Patterned conveyor belt

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

CONTACT US

Liutuodian Village, Boye County, Baoding City China.

Business Address

Gengzhuang Industrial Park, Shenze County, Shijiazhuang, Hebei, China

YOU CAN EMAIL US

PLEASE TELL US WHAT YOU NEED

Our engineers will contact you within 12 hours and provide free proposal and quotation.