Acid and alkali resistant conveyor belt

If you need customized products, Contact US !

Tag list

- 产品描述

-

Product Introduction

Acid and alkali resistant conveyor belts are specially designed for use in acidic or alkaline environments. They have excellent chemical corrosion resistance and good physical properties. They are widely used in chemical plants, fertilizer plants, paper mills, and other factories and mines for conveying materials containing acids or alkalis.

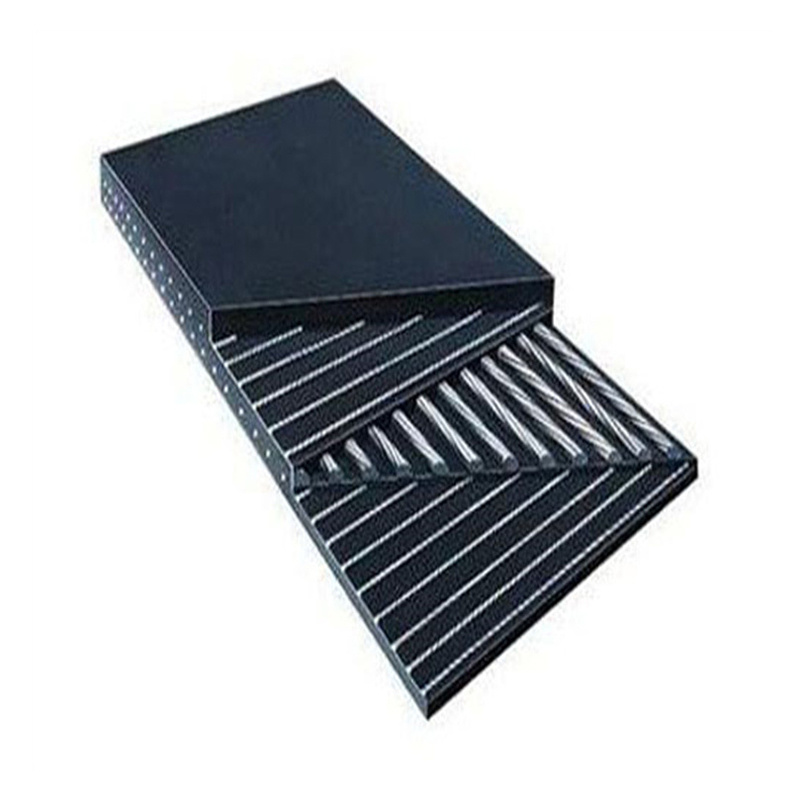

Material and Construction

The construction of acid and alkali resistant conveyor belts mainly includes the following parts:

Belt core: Usually made of cotton canvas, nylon canvas, or polyester canvas as the carcass layer. These materials have good acid and alkali resistance.

Cover rubber: The cover rubber is made of acid and alkali resistant materials and has good chemical corrosion resistance and physical properties. The thickness of the cover rubber can be 1.5-8.0mm on the working surface and 1.5-4.5mm on the non-working surface.

Application Scenarios

Acid and alkali resistant conveyor belts are suitable for the following scenarios:

Chemical plants: Used to convey various acidic or alkaline chemicals.

Fertilizer plants: Used to convey materials containing acid and alkali components in processes such as phosphate fertilizer manufacturing.

Paper mills: Used to convey acidic or alkaline pulp during pulping and papermaking.

Sea salt drying: Used in the process of seawater treatment and salt transportation.

Specifications and Standards

The specifications and standards of acid and alkali resistant conveyor belts are as follows:

Belt width: Ranges from 100mm to 3000mm

Layers: 1 to 10 layers

Acid and alkali resistant conveyor belt

If you need customized products, Contact US !

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

CONTACT US

Liutuodian Village, Boye County, Baoding City China.

Business Address

Gengzhuang Industrial Park, Shenze County, Shijiazhuang, Hebei, China

YOU CAN EMAIL US

PLEASE TELL US WHAT YOU NEED

Our engineers will contact you within 12 hours and provide free proposal and quotation.