Oil-resistant conveyor belt

If you need customized products, Contact US !

Category

Tag list

- 产品描述

-

Product Introduction

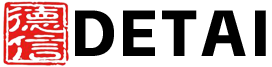

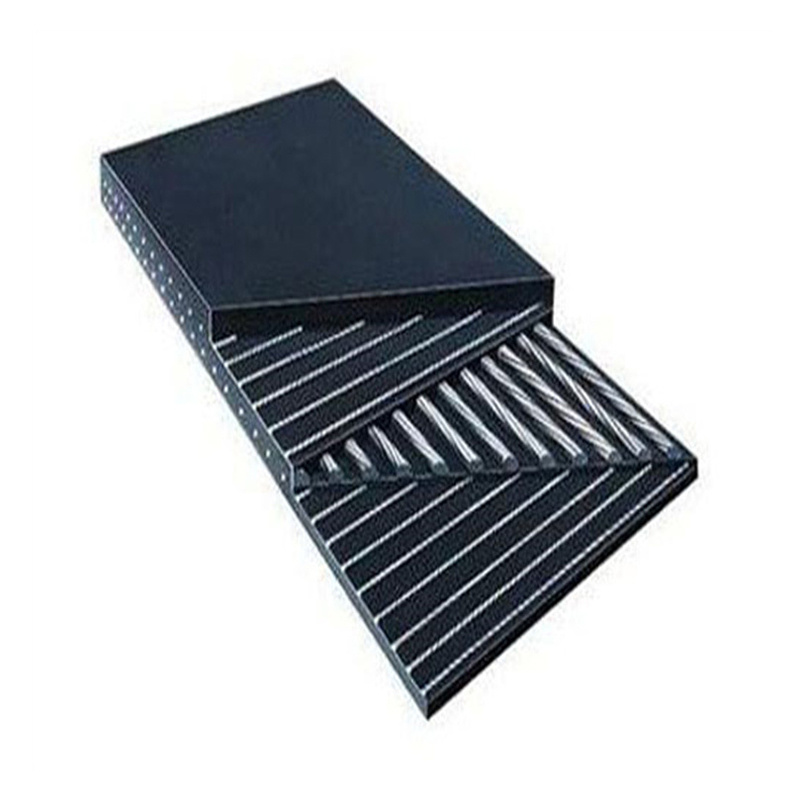

Oil-resistant conveyor belts are specially designed for conveying oil-containing materials. They possess excellent oil resistance and resistance to chemical solvents. Their main features include:

Material Selection: The cover rubber of oil-resistant conveyor belts uses nitrile rubber, a material with excellent oil resistance and resistance to chemical solvents. The reinforcing material can be selected from nylon canvas, all-cotton canvas, or polyester canvas according to customer needs.

Performance Characteristics: At room temperature, oil-resistant conveyor belts exhibit good resistance to mineral oils, vegetable oils, and animal fats. They have a low volume expansion rate, high strength retention, and a wide range of applications.

Usage Environment: Suitable for transporting oil-containing materials in environments such as chemical, oilfield, and food processing industries. They can be used in situations where oily substances or chemical solvents may be present.

Applications of Oil-Resistant Conveyor Belts

Oil-resistant conveyor belts are mainly used for conveying oil-containing materials or in environments where various working oils are contacted. Ordinary conveyor belts have poor resistance to various oils and organic solvents, and are easily degraded due to oil swelling and erosion. Oil-resistant conveyor belts effectively solve these problems, extending their service life.

Oil-resistant conveyor belt

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

CONTACT US

Liutuodian Village, Boye County, Baoding City China.

Business Address

Gengzhuang Industrial Park, Shenze County, Shijiazhuang, Hebei, China

YOU CAN EMAIL US

PLEASE TELL US WHAT YOU NEED

Our engineers will contact you within 12 hours and provide free proposal and quotation.