General purpose fabric core flame-retardant conveyor belt

If you need customized products, Contact US !

Tag list

- 产品描述

-

Product Introduction

A general-purpose fabric core flame-retardant conveyor belt is a special type of conveyor belt with flame-retardant properties, often used in places where safety is required in hazardous situations such as fires; this conveyor belt is specially treated based on a fabric core and has good flame-retardant, anti-static, impact-resistant, wear-resistant, and corrosion-resistant properties.

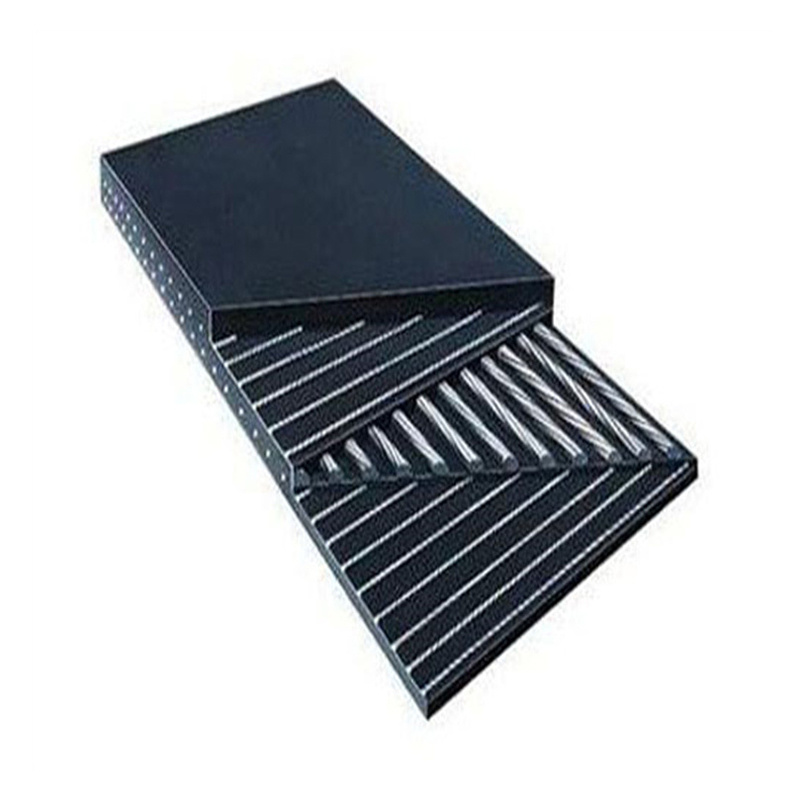

Structure and Manufacturing Process

Fabric core flame-retardant conveyor belts are usually made by calendering, molding, and vulcanizing nylon canvas or polyester canvas. The belt core uses polyester industrial filaments, nylon filaments, and cotton yarn woven into a three-to-five-layer integral structure, with high strength and stable transportation performance.

Application Fields and Characteristics

Fabric core flame-retardant conveyor belts are widely used in the chemical, coal, metallurgical, and power industries. It is suitable for conveying non-corrosive block, granular, and powdery materials, such as coal and other bulk materials or finished goods. This conveyor belt performs excellently in flammable and explosive environments and can ensure safety in hazardous situations.

General purpose fabric core flame-retardant conveyor belt

If you need customized products, Contact US !

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

CONTACT US

Liutuodian Village, Boye County, Baoding City China.

Business Address

Gengzhuang Industrial Park, Shenze County, Shijiazhuang, Hebei, China

YOU CAN EMAIL US

PLEASE TELL US WHAT YOU NEED

Our engineers will contact you within 12 hours and provide free proposal and quotation.